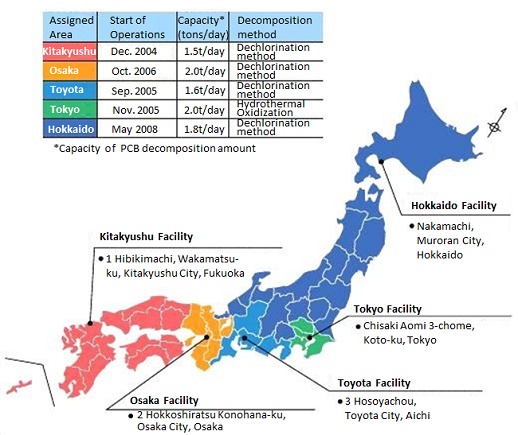

JESCO's Five Regional PCB Waste Treatment Facilities

JESCO will establish five regional plants nationwide. Kitakyushu Facility was the first to be completed and started operations in Dec. 2004. Toyota Facility, and Tokyo Facility started operations in 2005, and Osaka Facility started in 2006, and Hokkaido Facility started operations in 2008. Each facility is assigned by the government to treat PCB wastes of regions shown below.

- Framework for Transformers and Capacitors Treatment

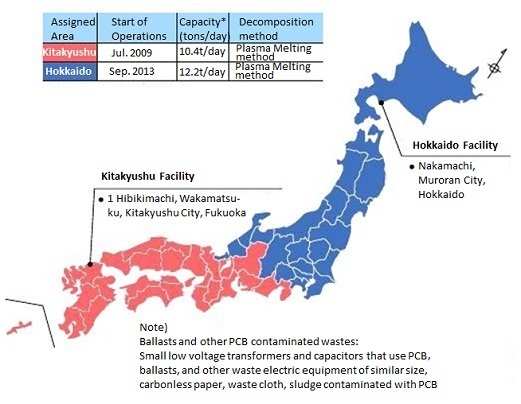

- Framework for Ballasts and Others Treatment

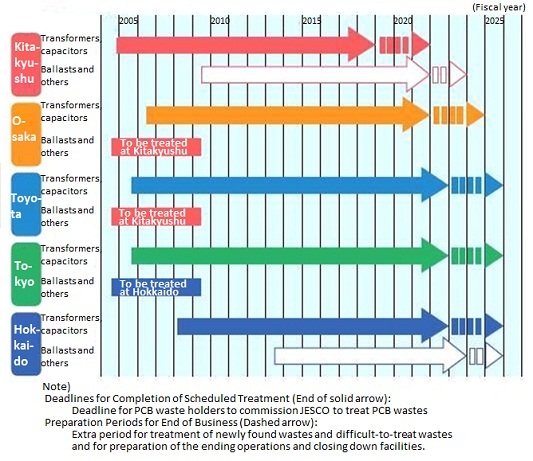

- New Treatment Deadlines and Preparation for Closing

- Treatment Methods

- Safety Measures Given Highest Priority

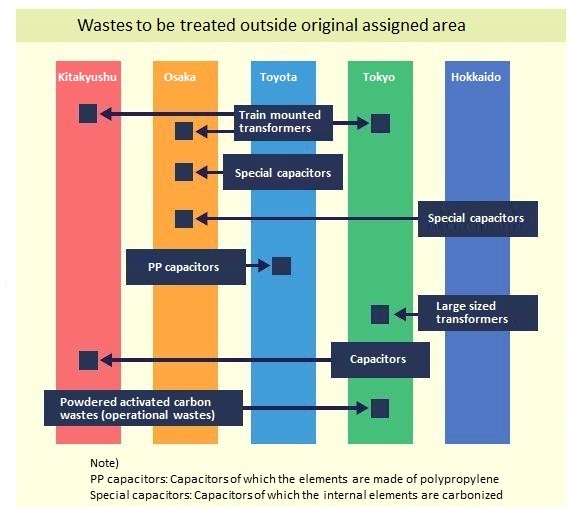

Framework for High-voltage Transformers and Capacitors Treatment

Framework for Ballasts and Other PCB-contaminated Waste Treatment

New Deadlines for Completion of Scheduled Treatment and Preparation Periods for End of Business

Treatment Methods

All JESCO facilities use only chemical decomposition methods, because they do not produce combustion gases. Tokyo Facility adopts the "hydrothermal oxidation decomposition method", and the other four facilities adopt the "dechlorination method".

In accordance with the company policy to carry out PCB waste treatment with priority on safe and reliable treatment, JESCO designs its facilities conforming to the concepts of adopting safe and sure treatment methods.

When determining treatment method for each facility, experts at the JESCO PCB Waste Treatment Project Exploratory Committee discuss necessary requirements for the facility, considering terms such as types of PCB wastes to treat and geographical constraints. In accordance with the conclusion of Committee discussions, JESCO invites public proposals on concrete treatment methods under WTO bidding rules, and carefully examines proposals from technical aspects and implementation aspects, and finally makes decision on which method to adopt.

In accordance with the company policy to carry out PCB waste treatment with priority on safe and reliable treatment, JESCO designs its facilities conforming to the concepts of adopting safe and sure treatment methods.

When determining treatment method for each facility, experts at the JESCO PCB Waste Treatment Project Exploratory Committee discuss necessary requirements for the facility, considering terms such as types of PCB wastes to treat and geographical constraints. In accordance with the conclusion of Committee discussions, JESCO invites public proposals on concrete treatment methods under WTO bidding rules, and carefully examines proposals from technical aspects and implementation aspects, and finally makes decision on which method to adopt.

Treatment Methods Adopted at Each Facility

| Facility | Pre-treatment | PCB Decomposition | ||||

| Name of Technology <Company that owns technology> |

Name of Technology <Company that owns technology> |

Reaction Condition | ||||

| Tempera -ture (degrees Celsius) |

Pressure (MPa) | Reaction time (hrs.) | Solvent, etc. | |||

| Kitakyushu (Phase 1) |

Precise Recovery Cleansing Method <Mitsui Engineering & Shipbuilding Co., Ltd.> Vacuum Thermal Recycling Method (VTR Method) <Z.E.R.O. Japan Co., Ltd.> |

Sodium Dispersion Method (SD Method) | 160 to 170 |

Ordinary Pressure | 1 (after dripping activating agent) |

Insulation Oil |

| Kitakyushu (Phase 2) |

- | Plasma Melting Method (Nippon Steel Coporation, Kobelco Eco-Solutions Co,.Ltd.) | Over 1,400 | 0.5kPa | Example: 0.5 for ballasts alone |

- |

| Toyota | Solvent Extraction Decomposition Method (SED Method)<Kobelco Eco-Solutions Co., Ltd.> | Ontario Hydro Technologies Sodium Dispersion Method (OSD Method) *3 <Nuclear Fuel Industries, Ltd.> |

60 to 70 | Ordinary Pressure | 6 | Liquid Paraffin |

| Tokyo |

MHI Chemical Cleansing Method *1<Mitsubishi Heavy Industries, Ltd.> | Hydrothermal Decomposition Method *2 <Mitsubishi Heavy Industries, Ltd.> | About 370 to 380 | About 26.5 |

About 3.5 |

Auxiliary Agent: NaOH |

| Osaka |

Solvent Cleansing Method <Toshiba Corporation> Vacuum Thermal Recycling Method (VTR Method) < Z.E.R.O. Japan Co., Ltd.> |

Catalyst Hydrogenation Dechlorination Method (Pd/C Method) 8.0pt'>*3 <Kanden Engineering Co., Ltd.> |

About 260 |

Ordinary Pressure |

6 |

Liquid Paraffin |

| Hokkaido |

Solvent Extraction Decomposition Method (SED Method) *1<Kobelco Eco-Solutions Co., Ltd.> |

Sodium Dispersion Method (SP Hybrid Method) *3 *1<Kobelco Eco-Solutions Co., Ltd.> |

115 to 120 |

Ordinary Pressure |

3 |

Liquid Paraffin, Accelerant: IPA |

| Hokkaido (Additional) |

- | Plasma Melting Method (Nippon Steel Coporation, Kobelco Eco-Solutions Co,.Ltd.) | Over 1,400 | 0.5kPa | Example: 0.5 for ballasts alone |

- |

*2 Classified as "Hydrothermal Oxidation Decomposition Method" under the Waste Management and Public Cleansing Law (Law No.137 of 1970)

*3 Classified as "Dechlorination Method" under the Waste Management and Public Cleansing Law (Law No.137 of 1970)

Safety Measures Given Highest Priority

JESCO has set up "the PCB Waste Treatment Exploratory Committee", composed of outside specialists. JESCO receives guidance and advice on technology, environmental and safety measures, safety design, management of safety and health of workers, etc.

[Basic Concept of JESCO's Facilities]

Adoption of Safe and Reliable PCB Treatment Method

Treatment methods and other matters are examined by experts in "the PCB Waste Treatment Exploratory Committee".

Multiple Safety Measures for Risk Management

JESCO gives its highest priority to safety, and takes all possible measures to ensure it. All facilities and equipment are designed so that processes are safe, and are fully equipped with operation monitoring systems. "Fail-safe" functions prevent malpractice or human errors, while multiple protective structures with "Safety Net" functions prevent damage to spread. Facilities are designed to withstand not only incidents that may occur during normal operation, but also unavoidable disasters such as earthquakes and typhoons, and in all cases operations are to shut down safely to minimize affect to the environment.

Information Disclosure of Operation Status

JESCO makes effort to actively disclose information from planning of facilities to operation status.