Government's Scheme to Promote PCB Waste Treatment

- Background of PCB Issues in Japan

- Structure of the "PCB Special Measures Law "

- PCB Treatment Standards in Japan

- PCB Treatment Methods permitted in Japan

- Certification Application for Detoxification of extremely low-level PCB wastes

- Government's Measures for the Safety of PCB Transportation

- Correlation Chart & Flow of PCB Waste Treatment

Background of PCB Issues in Japan

PCB, an industrially synthesized compound with excellent insulation and heat-resisting properties, was used for various items such as electrical insulation oil, heat medium oil in transformers and capacitors, and carbonless paper. Between the start of production in 1954 and end in 1972, approximately 59,000 tons of PCBs were manufactured in Japan.

However, the breakout of the Kanemi Oil Poisoning Case proved the toxicity of PCBs, and production and distribution of PCB was put to a stop via administrative guidances in 1972. The "Law Concerning the Examination and Regulation of Manufacture, etc., of Chemical Substances (Class I)" was enacted in 1973 and enforced in 1974. With this law, manufacturing, importing and new use of PCB was prohibited.

The establishment of PCB treatment facilities by private initiative did not succeed, because of strong opposition from residents living nearby candidate sites. Thus most of the banned PCB products were stored at their holder's sites, and fear of damage to the environment caused by leakage, misplacement or dumping of the wastes was a crucial issue.

With evidence of long-range transport of PCBs to regions where they have never been used and the consequent threats they pose to the environment of the whole world, UNEP adopted the "Stockholm Convention on Persistent Organic Pollutants (POPs)" in 2001, to reduce and abolish organic pollutants such as PCBs. Many advanced countries have already finished treating PCBs, and it is desirable for Japan to follow.

The Law concerning Special Measures for Promotion of Proper Treatment of PCB Wastes was enacted in Japan in 2001, and is now in effect to promote proper treatment of PCB waste. The Ministry of the Environment has put the promotion of PCB waste treatment at the top of the agenda for the 21st century.

Structure of the "PCB Special Measures Law "

The Law concerning Special Measures for Promotion of Proper Treatment of PCB Wastes (PCB Special Measures Law)(Law No.65 of 2001) was set up by the Central Government to establish framework for the prompt, secure and appropriate treatment of PCB wastes. The law defines the obligations of PCB waste holders, former PCB manufactures, central government and local governments, sets deadlines for treatment of PCB waste, and obliges the registration and public reporting of stored PCB waste.

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

| Safe and Steady Treatment | ||||||||||||||||||||||

* For outline of amended plan dated June 18, 2014 click here.  |

|

PCB Treatment Standards in Japan

Under the "Waste Disposal and Public Cleansing Law (Law No.137 of 1970)", treated PCB wastes must undergo PCB elimination tests according to waste type, and PCB concentration clear the following standards:

| Type of Waste | Standard (Test Method) |

| Waste PCB Oil(Treated) | 0.5mg/kg or under (Content Test Method) |

| Waste Acid or Waste Alkali | 0.03mg/l or under (Content Test Method) |

| Waste Plastic, Waste Metal or Pottery Waste | 0.5mg/kg or under -Solvent (Cleansing Solvent Test Method) 0.1micrograms/100cm2 or under (Wiping Method) 0.01mg/kg or under -Material (Material Collecting Method) |

| Others | 0.003mg/l or under (Dissolution Test Method) |

PCB Treatment Methods permitted in Japan

PCB Treatment Methods permitted in Japan

New PCB treatment technologies cannot be used in Japan until officially approved. The Waste Management Law regulates PCB waste treatment methods permitted in Japan. To get approval, the methods must be evaluated by the central government, and afterwards approved by the law. Besides PCB incineration at over 1,100 degrees celsius for over 2 seconds retention time, the following chemical treatment methods are allowed as of April 2005 (InformalTranslation).

| Form of PCB | Category | Treatment Method | Name of Technology | Corporation who Developed Technology |

| Waste PCB oil (Liquid Form) | De- compo- sition |

De- chlori- nation |

Base Caltalyzed Decomposition Method (BCD Method) | Ebara Corporation |

| Chemical Extraction Method | Tokyo Electric Power Company, Mitsui & Co., NEOS Corporation | |||

| Organic Alkari Metal Decomposition Method (t-BuOK Method) | KEPCO, Kanden Engineering | |||

| Catalyst hydrogenation Dechlorination Method (Pd/C Method) | ||||

| Ontario Hydro Technologies Sodium Dispersion Method (OSD Method) | Nuclear Fuel Industries, Ltd., Sumitomo Corporation | |||

| Sodium Dispersion Method (SD Method) | Nippon Soda Co., Ltd. | |||

| Metallic Sodium Dispersion Method (SP Method) | Kobelco Eco-Solutions Co,.Ltd., Okinawa Plant | |||

| Metallic Sodium Dechlorination Method (PCB Gone Method) | Organo Corporation | |||

| Metalic Sodium Dechlorination Method (MC Method) | Kyoueigiken, Tokyo Institute of Technology, NTRK | |||

| Catalyst Hydrogen Reduction Process | Nikko Rica Corporation, Takaoka Electric Manufacturing Co., Ltd., Showa Engineering Co., Ltd. and Kanae Corporation | |||

| Metallic Sodium Dechlorination Method (MR Method) | Hitachi, Ltd. | |||

| Hydro- thermal Oxidi- zation De- compo- sition |

Supercritical Hydroxide Decomposition Method | Organo Corporation | ||

| Hydrothermal Decomposition Method | Mitsubishi Heavy Industries, Ltd. | |||

| Reduc- tion and Thermo- chemis- try De- compo- sition |

Fused Catalyst Extraction Method (CEP Method) | Ebara Corporation, Mitsubishi Chemical | ||

| GPCR Process | Nippon Sharyo, Ltd., Tokyo Boueki | |||

| Photo- dis- inte- gration |

Ultraviolet Rays and Biotreatment Method | Railway Technical Research Institute, Mitsubishi Heavy Industries, Ltd. | ||

| Ultraviolet Rays and Distillation Method | Railway Technical Research Institute, Mitsubishi Heavy Industries, Ltd. | |||

| Ultraviolet Rays / Catalyst Decomposition Method | Toshiba Corporation | |||

| Plasma De- compo- sition |

Plasma Decompostion Method (PLASCON Method) | Itochu Corporation | ||

| PCB Contami- nated Waste (Solid PCB Waste) |

De- compo- sition |

Hydro- thermal Oxidi- zation De- compo- sition |

Supercritical Hydroxide Decomposition Method | Organo Corporation |

| Hydrothermal Decomposition Method | Mitsubishi Heavy Industries, Ltd. | |||

| Reduc- tion and Thermo- chemis- try De- compo- sition |

GPCR Process | Nippon Sharyo, Ltd., Tokyo Boueki | ||

| Mecha- nical Chemis- try De- compo- sition |

Radical Planet Method (RP Method) | Radical Planet Japan | ||

| Fusion De- compo- sition |

GeoMelt Method | ISV Japan, Ube Kozan, Nihonsouken, Kounoike Construction Co., Ltd., Hamamagumi | ||

| Plasma Enhancement Molten Method (PEM Furnace Method) | FIT, Kaswasaki Heavy Industries | |||

| Plasma Melting Method | Nippon Steel Coporation, Kobelco Eco-Solutions Co,.Ltd. | |||

| Removal | Cleansing | S-DEC Method | Nuclear Fuel Industries, Ltd., Sumitomo Corporation | |

| Solvent Extraction Decomposition Method (SED Method) | Kobelco Eco-Solutions Co,.Ltd. | |||

| Solvent Cleansing Method (Decontaksolv Method) | Kobelco Eco-Solutions Co,.Ltd. | |||

| Solvent Cleansing Method (SD Myers Method) | Organo Corporation | |||

| MHI Chemical Cleansing Method | Mitsubishi Heavy Industries, Ltd. | |||

| Solvent Cleansing Method (Denchuuken Method) | Central Research Institute of Electric Power Industry, FEPC | |||

| Precise Recovery Cleansing Method | Tokyo Electric Power Company, Mitsui & Co. | |||

| Solvent Cleansing Method | Toshiba Corporation | |||

| Solvent Extraction Method | Mitsubishi Heavy Industries, Ltd. | |||

| Separation | Vacuum Thermal Recycling Method(VTR Method) | Z.E.R.O. Japan Co., Ltd. | ||

| Vacuum Heating Method (Denchuuken Method) | Central Research Institute of Electric Power Industry, FEPC | |||

| Vacuum Heating Method | Aichi Electric Co., Ltd. | |||

| BCD Heating Method | Ebara Corporation | |||

| Non-oxygen Heating Method | Nippon Steel Corporation | |||

| Reduction Heating Method (RH-SP Method) | Kobelco Eco-Solutions Co,.Ltd. |

- Permission required for PCB Treatment facilities

The Waste Management Law requires incineration facilities, decomposition facilities, and cleaning and separating facilities to receive permits as industrial waste treatment facilities from the prefecture (or government-decreed cities) where established.

Certification Application for Detoxification of extremely low-level PCB wastes

To promote the appropriate treatment of PCB waste, the Ministry of the Environment implemented a certification system in Nov. 2009 so that private companies can treat waste electrical machinery contaminated by small amounts of PCB, using sophisticated technologies (mainly combustion using dioxin-controlled incinerators) in compliance with the Waste Management and Public Cleansing Law.

Amendments were made in the Basic Plan for PCB waste and relevent regulations, and now about 30 private companies approved by MoE or a local government treat low-level PCB wastes (0.5 to 100,000ppm for combustible PCB wastes / 0.5 to 5,000ppm for other PCB wastes).

Amendments were made in the Basic Plan for PCB waste and relevent regulations, and now about 30 private companies approved by MoE or a local government treat low-level PCB wastes (0.5 to 100,000ppm for combustible PCB wastes / 0.5 to 5,000ppm for other PCB wastes).

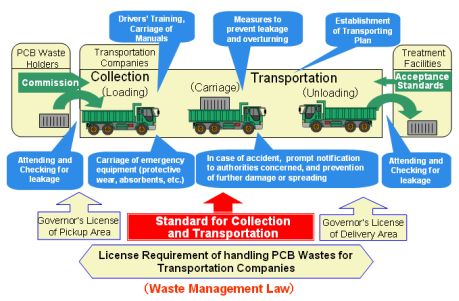

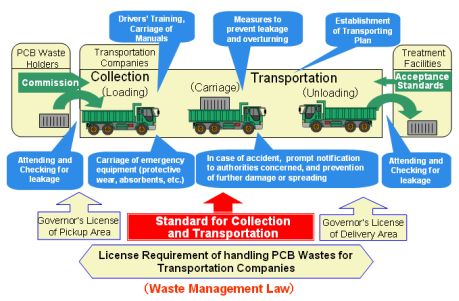

Government's Measures for the Safety of PCB Transportation

To transport wastes in Japan as a business, transportation companies need to obtain license from the prefecture (or government-decreed cities) where they wish to pickup or deliver wastes, in accordance with the Waste Management Law. To obtain license to transport PCB wastes, companies must meet requirements such as 1) airtight containers with measures to prevent leakage, 2)emergency equipment on vehicles and communication equipment for emergencies, 3)employees who handle PCBs (such as drivers) to be well acquainted with the nature of PCB, and have knowledge and skill to handle emergencies in case of an accident.

PCB waste holders must entrust licensed transportation companies to transport their PCB waste or, when transporting themselves they must follow the requirements of the prefectures or governmnent-decreed cities envolved. When carrying in PCB wastes to JESCO facilities, the transporter must also receive authorization from JESCO.

In March 2004, The Ministry of the Environment established the "PCB Waste Collection and Transport Guideline" (revised August 2011), which specifies technical requirements to adhere standards for transportation of PCB wastes, based on the Waste Management Law.

Contents of the "PCB Waste Collection and Transport Guideline"

PCB waste holders must entrust licensed transportation companies to transport their PCB waste or, when transporting themselves they must follow the requirements of the prefectures or governmnent-decreed cities envolved. When carrying in PCB wastes to JESCO facilities, the transporter must also receive authorization from JESCO.

In March 2004, The Ministry of the Environment established the "PCB Waste Collection and Transport Guideline" (revised August 2011), which specifies technical requirements to adhere standards for transportation of PCB wastes, based on the Waste Management Law.

Contents of the "PCB Waste Collection and Transport Guideline"

| [Collection and Transportation] 1. Preliminary Survey and Contract 2. Collection and Transportation Method 3. Signs and Labels 4. Documents to Carry |

[Safety and Operation Management] 1. Safety Management System 2. Training of Employees Involved 3. Transportation Plan 4. Operation Management 5. Reporting |

| [Carriage Containers] 1. Standard of Containers 2. Types of Containers 3. Testing of Containers 4. Selecting of Containers 5. Reuse of Containers 6. Maintenance of Containers |

[In Case of Emergency] 1. Preventive Measures 2. Emergency Contact List 3. Emergency Measures |

Correlation Chart & Flow of PCB Waste Treatment

Correlation Chart & Flow of PCB Waste Treatment

JESCO has established and operates five regional plants nationwide, according to the PCB Waste Treatment Basic Plan, established by the Ministry of the Environment (MOE). Construction fees are subsidized by the central government, and JESCO will follow directions of the central government and the local authority.

PCB waste holders must report to prefectures the status of their PCB wastes each year, and must treat the wastes by deadline set by the government or entrust JESCO to treat the wastes by JESCO's deadlines for completion of scheduled treatment. To carry in the wastes to JESCO facilities, the holders must entrust a licensed tranportation company.